PLYWOOD INCLINED BEAM CAPACITY CHECK

BS 5268-2:2002

1.0 INPUT DATA

1.1 Geometrical Properties

Span (horizontal projection) Lhorizontal = mm

Plywood Thickness h = mm

Plywood Width b = mm

Angle of inclination θ = deg

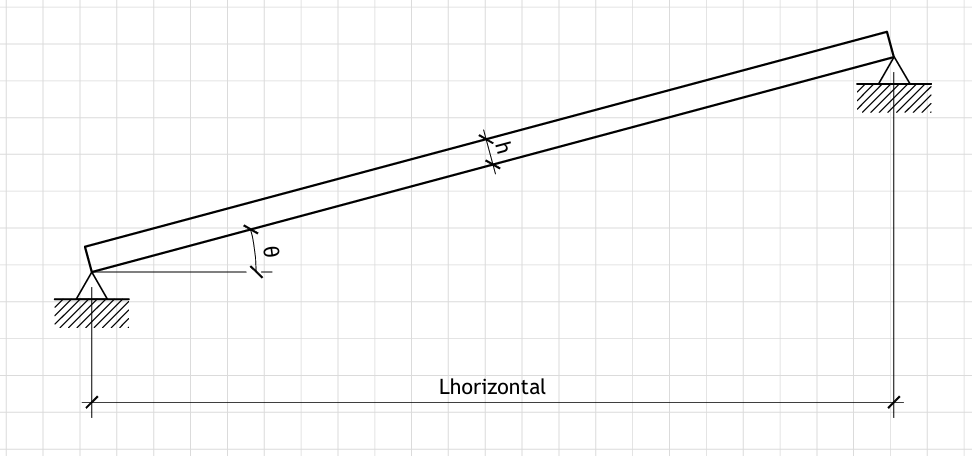

Figure 1: Geometry

Plywood inclined at angle θ with horizontal span L_horizontal

Effective Span along the inclined length Leff,inclined =

Lhorizontal/cos(θ)

Leff,inclined = 380/cos(54°) = 646.15 mm

1.2 Loading

Uniformly Distributed Load (UDL) qLL = kPa

Total UDL on specified width wvert =

qLL×b/1000

wvert = 2×1000/1000 = 2.00 kN/mm

Concentrated Load (mid-span) PL,LL = kN

1.3 Material Properties (BS 5268-2:2002)

Characteristic Bending Stress fm,g = N/mm²

Characteristic Shear Stress fv,g = N/mm²

Characteristic Compression Stress fc,g = N/mm²

Mean Modulus of Elasticity Emean = N/mm²

Minimum Modulus of Elasticity Emin = N/mm²

1.4 Modification Factors

Load Duration Factor K3 =

Depth Factor K7 =

Load Sharing Factor K8 =

Compression Factor K22 =

2.0 CALCULATIONS

2.1 Section Properties

Section Area A = b×h

A = 1000×12 = 12000.00 mm²

Second Moment of Area I = (b×h3)/12

I = 1000×12³/12 = 144000.00 mm⁴

Section Modulus Z = (b×h2)/6

Z = 1000×12²/6 = 24000.00 mm³

2.2 Load Resolution into Components

Resolve loads into components normal to and along the beam

UDL perpendicular to beam wperp =

wvert×cos(θ)

wperp = 2.00×cos(54°) = 1.18 kN/mm

UDL parallel to beam wparallel =

wvert×sin(θ)

wparallel = 2.00×sin(54°) = 1.62 kN/mm

Concentrated load perpendicular to beam PL,perp =

PL,LL×cos(θ)

PL,perp = 1.5×cos(54°) = 0.882 kN

Concentrated load parallel to beam PL,parallel =

PL,LL×sin(θ)

PL,parallel = 1.5×sin(54°) = 1.214 kN

2.3 Applied Actions

Maximum Bending Moment

MUDL =

wperp×Leff,inclined²/8

MUDL = 1.18×646.15²/8 = 61606.96 kN.mm

MPL =

PL,perp×Leff,inclined/4

MPL = 0.882×646.15/4 = 142.55 kN.mm

Maximum Bending Moment Mmax = max(MUDL;

MPL)

Mmax = max(61606.96; 142.55) = 61606.96 kN.mm

Maximum Shear Force

VUDL =

wperp×Leff,inclined/2

VUDL = 1.18×646.15/2 = 381.43 kN

VPL = PL,perp/2

VPL = 0.882/2 = 0.441 kN

Maximum Shear Force Vmax = max(VUDL;

VPL)

Vmax = max(381.43; 0.441) = 381.43 kN

Maximum Axial Force (Compression)

Nmax =

wparallel×Leff,inclined +

PL,parallel

Nmax = 1.62×646.15 + 1.214 = 1047.04 kN

2.4 Serviceability Check: Deflection

Edeflection = Emean×K9

(assuming K9 = 1.0)

Edeflection = 5800×1.0 = 5800.00 N/mm²

Bending deflection from UDL δb,UDL =

5×wperp×Leff,inclined⁴/(384×Edeflection×I)

δb,UDL = 5×1180.00×646.15⁴/(384×5800.00×144000.00) = 8.44 mm

Bending deflection from PL δb,PL =

PL,perp×Leff,inclined³/(48×Edeflection×I)

δb,PL = 882.00×646.15³/(48×5800.00×144000.00) = 0.06 mm

Maximum bending deflection δb,max =

max(δb,UDL; δb,PL)

δb,max = max(8.44; 0.06) = 8.44 mm

Permissible deflection δadm =

Leff,inclined/90

δadm = 646.15/90 = 7.18 mm

Deflection Check = FAIL

(δb,max = 8.44 >

δadm = 7.18 mm)

2.5 Strength Check: Bending

Permissible bending stress σm,adm =

fm,g×K3×K7×K8

σm,adm = 6×1.25×1.00×1.00 = 7.50 N/mm²

Applied bending stress σm,app =

Mmax/Z

σm,app = 61606.96×1000/24000.00 =

2567.0 N/mm²

Bending Check = FAIL

(σm,app = 2548.08 >

σm,adm = 7.50 N/mm²)

2.6 Strength Check: Shear

Permissible shear stress τadm =

fv,g×K3×K8

τadm = 0.5×1.25×1.00 = 0.63 N/mm²

Applied shear stress τapp =

1.5×Vmax/A

τapp = 1.5×381.43×1000/12000.00 =

47.68 N/mm²

Shear Check = FAIL

(τapp = 47.47 >

τadm = 0.63 N/mm²)

2.7 Strength Check: Axial Compression

Permissible compression stress σc,adm =

fc,g×K3×K22×K8

σc,adm = 6×1.25×1.00×1.00 = 7.50 N/mm²

Applied axial compression stress σc,app =

Nmax/A

σc,app = 1047.04×1000/12000.00 =

87.25 N/mm²

Axial Check = FAIL

(σc,app = 87.17 >

σc,adm = 7.50 N/mm²)

2.8 Combined Bending and Compression Check

Interaction ratio = (σm,app/σm,adm) +

(σc,app/σc,adm)

Interaction ratio = (2567.0/7.50) + (87.25/7.50) = 353.90

Combined Stress Check = FAIL

(Interaction ratio = 353.90 > 1.0)

*** OUTPUT SUMMARY ***

Verification Results

Deflection Check: FAIL

Bending Stress Check: FAIL

Shear Stress Check: FAIL

Axial Stress Check: FAIL

Combined Stress Check: FAIL

Detailed Results

Section Area A = 12000.00

mm²

Second Moment of Area I = 144000.00 mm⁴

Section Modulus Z = 24000.00

mm³

Maximum Bending Moment Mmax = 61606.96 kN.mm

Maximum Shear Force Vmax = 381.43 kN

Maximum Axial Force Nmax = 1047.04 kN

Maximum Deflection δb,max = 8.44 mm

RESULTS

DESIGN FAILS - ADDITIONAL STRENGTH OR REINFORCEMENT REQUIRED